Difference Between Lubricated and Oil-Free Air Compressors

Share

Understanding the Two Types of Air Compressors

When buying an air compressor, one of the first choices you’ll have to make is between lubricated and oil-free models. Both do the same basic job — compress air — but they’re built for different kinds of work.

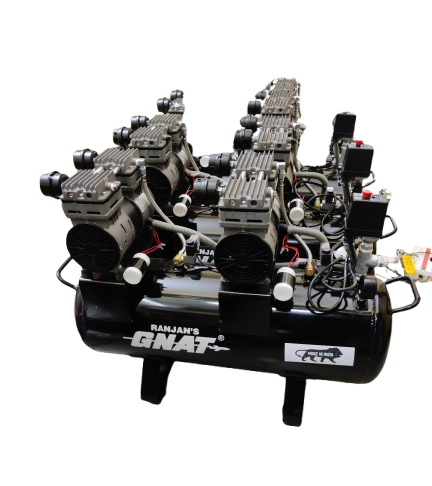

Lubricated Air Compressors

These compressors use oil to lubricate their moving parts, keeping them cool and running smoothly.

Key Features:

- Built for long hours and heavy-duty use

- Ideal for factories, workshops, garages, and construction sites

- Runs quietly and lasts longer due to better lubrication

- Needs regular oil changes and maintenance

- Strong performance for industrial work

Best For:

Manufacturing, automotive, drilling, painting, and other industries where clean air is not a strict requirement.

Oil-Free Air Compressors

Oil-free compressors don’t use oil inside the compression chamber. Instead, they have special coatings or materials that allow parts to move smoothly without lubrication.

Key Features:

- Provides clean, oil-free air

- Requires very little maintenance

- Light and portable

- Ideal for jobs that need clean air output

Best For:

Dental clinics, hospitals, food packaging, electronics, and painting work where even a small trace of oil can cause problems.

Quick Comparison

| Feature | Lubricated | Oil-Free |

|---|---|---|

| Maintenance | Regular oil checks | Minimal |

| Air Quality | May contain oil particles | 100% oil-free |

| Durability | Longer life | Slightly shorter |

| Use Type | Heavy-duty | Light to medium |

| Ideal For | Industrial, mechanical work | Clean air industries |

✅ Conclusion

If you need a compressor for continuous, heavy use, go for a lubricated model. If you work in medical, food, or precision industries, choose an oil-free compressor.

At GNAT, both models are by a 1-year warranty with full after-sales support.