Common Air Compressor Problems and How to Fix Them

Share

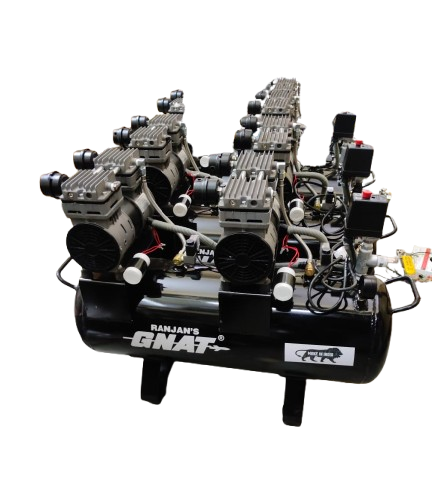

Keeping Your Air Compressor in Good Shape

Even the best machines need care. Regular checks can help you avoid downtime and keep your compressor working smoothly for years. Here are some common issues and simple ways to fix them.

1. Compressor Not Starting

Possible Causes:

- Power supply problem

- Faulty switch or fuse

- Low oil level (for lubricated models)

Quick Fix:

- Check the plug, fuse, and power socket

- Refill oil if low

- Call for service if motor doesn’t start after checks

2. Low Pressure or Air Leaks

Possible Causes:

- Leaks in hose or fittings

- Dirty filters or blocked intake

- Worn piston rings

Quick Fix:

- Tighten all fittings and check for air leaks using soapy water

- Clean or replace the air filter

- Get the compressor serviced if pressure is still low

3. Overheating

Possible Causes:

- Poor ventilation

- Continuous running without rest

- Low oil level

Quick Fix:

- Place the compressor in a well-ventilated area

- Let it cool between uses

- Check oil level regularly

4. Unusual Noise or Vibration

Possible Causes:

- Loose bolts or mounting

- Worn bearings or belt (for belt-driven models)

Quick Fix:

- Tighten bolts and check alignment

- Replace worn belts or parts during servicing

5. Oil or Water in Air Line

Possible Causes:

- Overfilled oil tank

- Moisture not drained from tank

Quick Fix:

- Maintain proper oil levels

- Drain tank regularly to remove water buildup

✅ Final Tip

Regular maintenance is the key.

- Check oil and filters weekly

- Drain moisture after use

- Clean intake vents

- Schedule servicing every few months

At GNAT, all our compressors come with a 1-year warranty, readily available spares, and after-sales service across India — so your business never stops.